In the beginning, I started to create an article about the future-proof Automation Control System. However, I found that giving a good perspective to readers is the key to a common understanding. Therefore I decided to describe the evolution of Automation Control Systems over time. I will also focus on the impact of evolution on the manning onboard the ships. Understanding how technology changes and influences reduce of manning is the key to understanding how future-proof systems have to be built. It’s also important to look, at what is pushing us towards MASS and remote control.

First Reduce manning forced by Automation!

Reduce of manning started in the 18th century, together with the first industrial revolution. However, all machines are operated by humans, so we cannot call it automation. But the first significant evolution in automation came in the form of Joseph Marie Jacquard in 1801. His Jacquard loom used punched cards to control the weaving process, allowing for the production of intricate patterns. This is the first machine that controls the process, with the use of different devices.

The significant role of feedback

The first feedback control was used already by the Egyptians, in the water clock. However, for the significant impact, of feedback role in automation, we need to wait a bit.

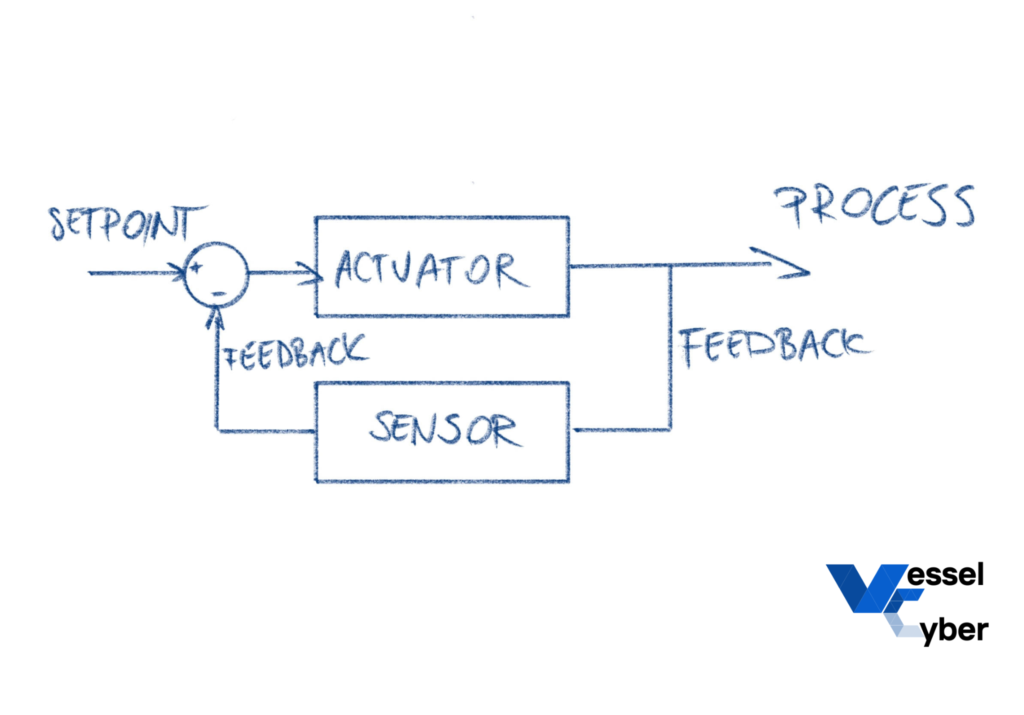

It was only in the 1930s that a theory of feedback control was first developed by Black and Nyquist at Bell Labs. They were studying feedback as a means to linearize repeater amplifiers for telephone lines, but they had problems with what they called “singing”. This was simply the onset of closed-loop instability when the feedback gain was set too high, transforming the amplifier into an oscillator(1). This was the first significant update, since Jacquard’s machine. This allows for automatic control of the processes. And this build-up control structure as we know it today. ( Actuator -> Process -> Feedback -> Actuator).

Around the same time, PID control was established. A nonlinear, continuous control loop was a new concept, therefore it needed some time to gain popularity. From this moment we reach more frequent updates in technology. During the second world war and the development of radar, we pushed automatic control systems to the next level. We mastered, not linear control systems, around 1950. But the first revolution showed up in 1945 with ENIAC.

Role of Feedback in reducing manning

The feedback loop was actually the first moment when automation reduced manning for the process. Instead of people who supervise the process, it is done automatically. This is why, complicated processes require less supervision. Some parts of the process could be realized automatically.

From this moment we look forward to reducing manning in the engine room.

Digitalization as Revolution of Automation Control Systems

ENIAC has changed everything. We see how our lives look today, compared to 1945. Everyone has a powerful device in his pocket! Therefore we don’t need to wait long for the wide use of digital technology in control processes. In 1968 general motors invited the first Programmable Logic Controller – Modicon 084. This has a serious impact on the reduction of manning during the control process. Only 3 years later, engineers from Texas Instruments presented the first microcontrollers.

PLCs and Microcontrollers revolutionize Automation Control Systems. Microcontrollers are designed exactly for the purpose of the needed process. Therefore, they can be relatively cheap, and they were widely used in embedded applications. PLC, on the other hand, can connect several embedded applications, and trigger actions in microcontrollers. This functionality, in a natural way, has to build SCADA systems or Distributed Control Systems. Same way as we know them today.

This was a huge step forward in reducing manning. One person could supervise several processes onboard. From this time it was clear, that we would have much less crew onboard. Around the 1970’s on the average ship we still have around 50 people onboard the ship. We still need to wait for the introduction of this technology onboard the ships, but the direction of development was clear. The number of people to supervise the processes will significantly go down!

Current Automation Systems

Today industrial automation systems are mainly based on Scada. With the use of different protocols by different Vendors, with some well-established standards like Profinet/Profibus, Modbus, EtherCAT, CANBUS, OPC classic, and OPC-UA. Principals working for all the protocols are the same: They communicate components of the systems. They have different architecture, and as always, the devil is in the details. This technology allows us to build more complex and complicated Automation Control Systems.

Evolution of Automation Control Systems – Impact on reduction

Today’s ships are 3-4 times bigger than ships from the 1970s. At the same time, these bigger ships, are operated by less than 20 people onboard. And development in technology will continue, the same as the reduction of manning. The market is going in the direction of remote-controlled ships, and the so-called MASS. ( Maritime Autonomous Surface Ships).

Conclusion about Automation Control Systems

The next technology update, which is currently developing and established is IoT (Internet of Things) and the use of the Cloud in Industrial Automation. It gives additional benefits and flexibility in building Automation Control Systems. This is why we need the next evolution in the system onboard. Standards in the integration of Cloud, IoT, Cybersecurity, and Scada, need to be urgently developed, for the maritime industry. What how the proper system of the future should look like?

For this, I highly recommend reading our next article!