What is big data?

Big data is basically a collection of a big volume of data, which is growing with time. Traditional methods of data recordings are not efficient to record all parameters of the vessel. This data has to be used in an efficient way. By analyzing big data in maritime industry, every shipping and shipbuilding company can do serious savings! How to achieve this? Read this post of course!

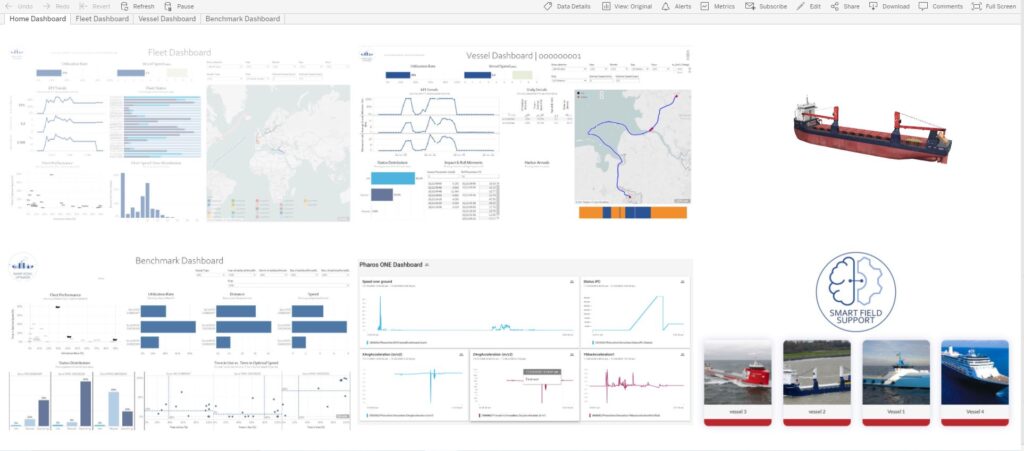

Ok, we have Big data, and this is a big thing. But why we need it? The main purpose of big data is efficient management and maintenance of the equipment. For the maritime industry, everything is a little bit special. However, finally, we have solutions like in other industries. We have Smart Vessel Optimizer!

Many thanks to Bram van den Boom for his time and help in the creation of this article!

Big data system over time

Data systems can be compared with a new employee. That employee stays with you forever and is capable of remembering everything. Completely everything that happened on all your vessels from the day he started. He shares all his experiences with everyone in the value chain. All the time, whenever the information is needed to support decisions.

Big data in the maritime industry – Smart Vessel Optimizer

Smart Vessel Optimizer is a company with a strong background in Big Data. They gain experience with manufacturing industries like pharmacy or chemical. They found out that vessels are not that far away from the industrial parks. Machinery onboard is very similar to production lines. So some of the applications You can copy from industrial solution to the maritime. However, the problem starts when we have to sail the ship.

Every type of ship has its own specification. A cruise ship is sailing differently from the Pipelayer. Container ships are sailing in different ways than dredgers. Smart Vessel Optimizer finds out that the same equipment is operated differently by different ships. This is forwarding us to the first important point.

Technical Profile of a Ship for Big Data

In industrial environments, it is very common to compare similar machines, production lines, and factories on a couple of KPI’s. This way you create an overview of the overtime performance and what your best / worst performers are. This way you can set your best performer as the Benchmark and from there on optimizing the underperformers in a really efficient way. Fuel is one and with it being quite a big impact on the Opex very important but there are many more.

Overal Equipment Effectiveness

Think of ‘overall equipment Effectiveness’ (OEE) this calculates the maximum available time to produce at maximin capacity and compares that with the actual performance. This way you detect (over time) how many unnecessary waiting hours you have per vessel, how much ballast you transport, how much empty/not full trips you make etc. KPI’s can be very easy as well. For example, think of automatic tracking of running hours for maintenance, automatic MRV/DCS reporting, tracking of engine load vs speed development to detect fouling. At the Smart Vessel Optimizer office, they have already more than 100 different maritime performance KPI’s. Therefore, they are divided over different vessel types and in the categories: operational performance, Ecological performance, Technical performance, financial performance. Therefore, the number of KPI’s is growing on a weekly base.

Example of KPI

As Your KPI is fuel, it is quite clear that You have to monitor all big energy consumers and generators. Then You can directly know, when and why the power consumption was too high. An additional advantage of power consumption monitoring at the big consumers is that You can find out if the pump or compressor is still in good condition. If the power consumption of certain pumps is higher than before, then You can expect some technical problems. Incorrect alignment after maintenance work. Maybe motor requires to replace ball bearings? This is the first point for the crew to investigate the device.

Data from different systems

The biggest challenge is that data coming from different systems need to combine. On today’s vessels, these separate systems are not always designed to share data, in the first place. You can compare that with asking a team of people that come from different countries, have never met each other. They do not understand each other’s language and do not work in the same rhythm to work together on a task. To do so you need a system that is capable of translating all the languages, synchronize all their work rhythms, have a central point of information gathering and sharing and have clear tasks (the tasks being reporting on specific KPI’s).

The Smart Vessel Optimizer system is capable of communicating with 600 different PLC types. It is using over 100 common industrial communication protocols. System has also extended portfolio of extra sensor technologies. It is able to always unlock the correct I/O in a correct sample rate with the right accuracy. This allowes to bring all that information to one central place.

Analyzes of big data in Maritime

Because of previous experience, they have already experience with records. For example, they can estimate how long should take an interval for maintenance of an AC compressor. One of my favorite quotes is “You cannot predict the future, but You can analyze the past”. Data analytics are the base. This helps to understand what went wrong or what we could do better. With all this knowledge, we can improve processes.

AI – Artificial Intelligence in data analytics

There is a lot of information to deduct by normal data analytics and by combining the data input with domain experts from the vessel builders/owners. Though there will be a time where the data is simply to large to go through by hand and a person is not capable of overseeing the whole data set. This is where AI/ML can support. The systems are capable of learning by looking at what the people do.

This way they understand what type of information we like to see from the data set and start to deduct correlations/anomalies and other information themselves. By presenting that to a domain expert who approves/disapproves the systems learn and become better. Therefore the Smart Vessel Optimizer there is an AI embedded. To support with analyzing the large amount of data. In conclusion, the system is set up in a way it can share information with other applications/AI’s as well for more specific analyses

What are Your benefits of Big Data in Maritime?

There are several of benefits of big data. Cost optimization, improve of efficiency, better control and monitoring. But the most important is, that solutions can be easily adjust to the needs of Your company. Doesen’t matter what will be Your KPI. You can improve your processes!

In conclusion, I strongly belive, that data analitics will improve maritime industry! I am waiting to see Your opinions about big data in maritime industry.

[…] The big thing – Big data in Maritime industry Search for: […]

[…] condition monitoring, or name it is You want. Some of You could read something about this already. (Here is our article about big data in maritime industry) This kind of system is constantly monitoring the parameters of machinery. Systems can measure […]

[…] Additionally, this kind of system can be equipped with Artificial intelligence or machine learning, however, this is not a top requirement. The most important is to know what kind of events You want to prevent. Do Your measurements and prevent the event before it happen! We write some article about the data, check it here! […]