Basically, proximity switches are responsible to detect objects. Objects nearby without physical contact. Additionally, proximity sensors can be used to measure the distance between the objects. However, we have a lot of different types of proximity sensors. This means that You have to be sure, which sensor you can replace with another one. Because they are using different physical reactions, You have to always replace them with the correct type of sensor. In the beginning, will be good to divide to main questions proximity switch and proximity sensor.

Proximity switch vs proximity sensor

I would like to explain shortly explain what is the difference between these 2 devices. A proximity switch contains a proximity sensor and operational contacts. Contacts will control the automation/sequence behind. Sensors can monitor the value. A monitoring system based on value can operate the process. However, this is not a proximity switch. This is a process control based on a proximity sensor. Additionally, sensors can be combine with contacts, to take the action immediately. This element, which switches contacts directly on the proximity sensor is a proximity switch. With high possibility, You can find both of these solutions in the automation system onboard the vessels.

Inductive proximity switch

For instance, the most popular proximity sensors are emitting electromagnetic fields and measure changes in the returning field. They are very simple, high reliability and long time solutions. They are also quite cheap and easy to replace.

Proximity sensors can easily adapt to monitor vibration. If they are install properly, they will be active if the machine starts to vibrate and move a little bit closer to the sensor. This will generate the alarm in the system, and the device needs to be checked. Sometimes electromagnetic field sensors are also called inductive sensors. The principle of working is the same in these 2 types of sensors. They can detect aluminum, copper, iron, steel, etc. The typical range of electromagnetic sensors is between 2-40mm.

Capacitive proximity switch

Another very popular proximity sensors are the capacitive sensor. Capacitive sensors can detect metallic and nonmetallic objects. As well as liquids, which is their biggest advantage in comparison to inductive sensors. That’s why they are coming more commonly to installations in the last years. Capacitive and Inductive sensors can be easily misled by their look. However, they have completely different principles of working.

Induction sensor is

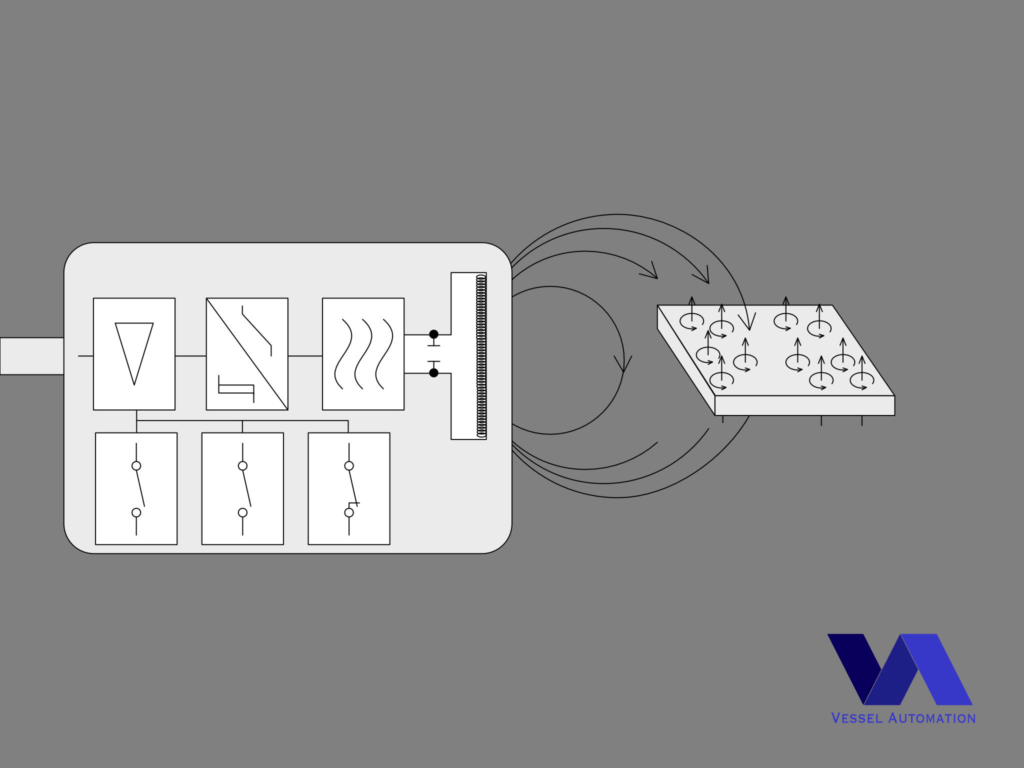

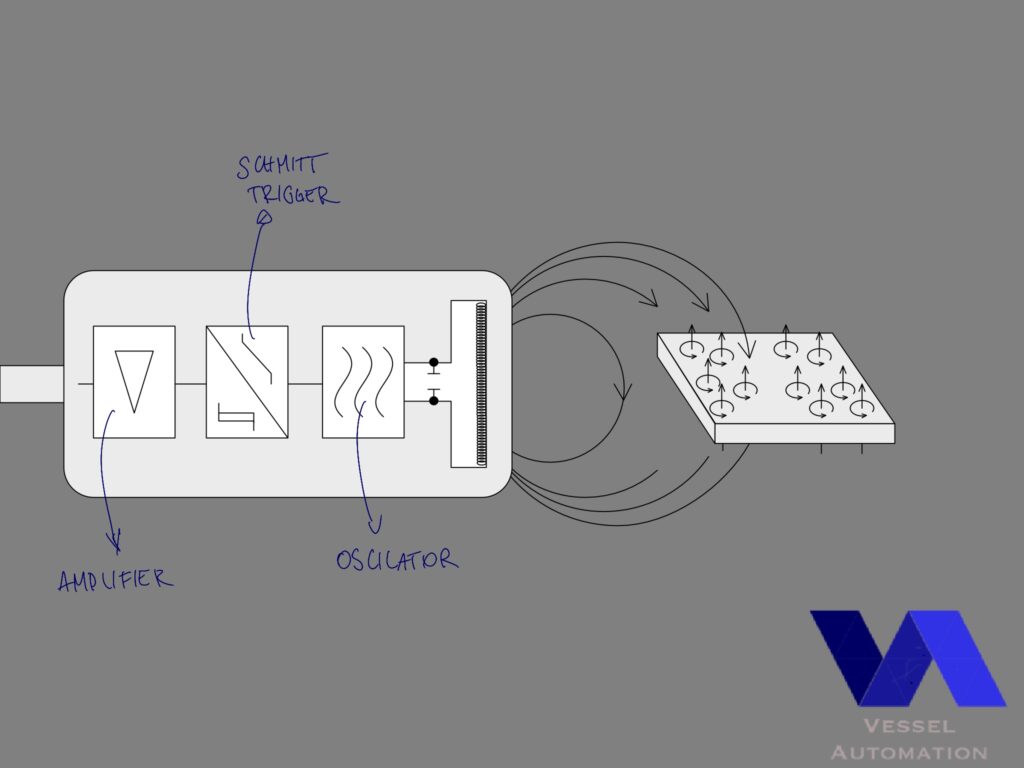

Capacitive sensors are more complicated electronic devices. They have multiplexers, Oscillators, counter, and amplifiers. So this is compact technology, which is very efficient and very accurate. Additionally, it can measure the thickness or density of non-conductive materials. The disadvantage is that you have to position them very accurately, so in maritime use, they could require repositioning after some time, due to vibrations.

Optical proximity switch

These are the two most common proximity sensors used onboard. However, You can found also optical proximity switch. With using the photocell. However, the most popular optical sensors with infrared. They are basically photodetectors, which detect reflections nearby. A good example is smoke detectors with photoelectric cells. I already describe them on the occasion of fire protection systems. Here you can find the post.

This method is also very good to measure the vibration. If You place the object in “sweet spot”, all deviations from the position will be monitored. When object will be to far, there will be not a per

Ultrasonic proximity sensor

The last type which You can meet onboard is the ultrasonic sensors. I think they will become more and more popular in the next years. They work on the principle of sound waves to detect objects, including glass and plastic. They are perfect for continued monitoring of fluids. Ultrasonic sensors are very accurate and highly reliable sensors.

These 4 types of devices are the most popular proximity sensors. Additionally, operational contact can modify sensors to proximity switches. With them, You can generate an alarm, or control the operation/process very easy. As You can see, there is a lot of different types of sensors that can help you control the process.

Be sure that You use correct sensor to Your needs!

If You like this post, below You can subscribe our newsletter!